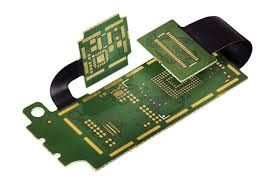

Stiffeners Are Used in Rigid-Flex PCB Fabrication

The flex circuit board (FPC) can be a complicated piece of technology, and there are many areas in which stiffeners must be used. The function of stiffeners is to offer mechanical support for the flex area. They are not required to fulfill any electrical functions, and they also do not play a role in the overall functioning of the PCB. They are necessary, however, because they make the flex circuit board more reliable and able to withstand various stresses and environments.

Stiffeners are available in a variety of materials, and the choice depends on the specific design and end product demand. Stainless steel, FR-4, and Polyimide are some of the most popular materials for rigid flex pcb fabrication stiffeners. Depending on the needs of the application, different thicknesses can be chosen for the stiffeners.

FR-4 stiffeners are typically used to help stabilize areas of the flex circuit with components and connectors attached. Without them, the flex circuit would be susceptible to damage when the board is bent at or adjacent to those locations. Additionally, the stiffeners can protect the solder joints from being cracked or compromised during bending.

What Types of Stiffeners Are Used in Rigid-Flex PCB Fabrication?

When selecting a stiffener, it is important to remember that the material must be compatible with the adhesive system being used on the flex circuit board. For example, a flex circuit that is designed to use ZIF (zero insertion force) connectors requires stiffeners that can be attached with pressure-sensitive adhesive. This is possible with PI, aluminum, and FR-4 stiffeners that are bonded using an adhesive system that is compatible with those materials.

In addition to the type of stiffener material, it is important to consider the size that will be needed. This is because the stiffener’s size can impact how much slack will be allowed in the flex circuit board. In order to avoid excess slack, the stiffener should be carefully cut to ensure that it is a perfect fit with the flex circuit board.

For instance, if the flex circuit board is to be produced in a double-layer configuration, it will likely require both a FR-4 and a PI stiffener. The FR-4 stiffener will help stabilize each end of the circuit, while the PI stiffener will be applied underneath the gold fingers to allow for the proper attachment of the ZIF connectors.

For complex applications that require a high degree of rigidity, metal sheets such as aluminum and stainless steel may be used. These sheets have properties that cannot be achieved with traditional rigid-flex PCB materials, including conductivity, moldability, and durability. These types of stiffeners are usually bonded to the flex circuit using an automated assembly process that is similar to the manufacturing processes used for rigid PCBs.

This helps to reduce the time and cost of rigid-flex PCB fabrication. In some cases, the rigid-flex boards can be molded into a 3-D structure to complete the final product. This makes them a suitable solution for a wide range of products, including electronic appliances, medical devices, and automotive parts.